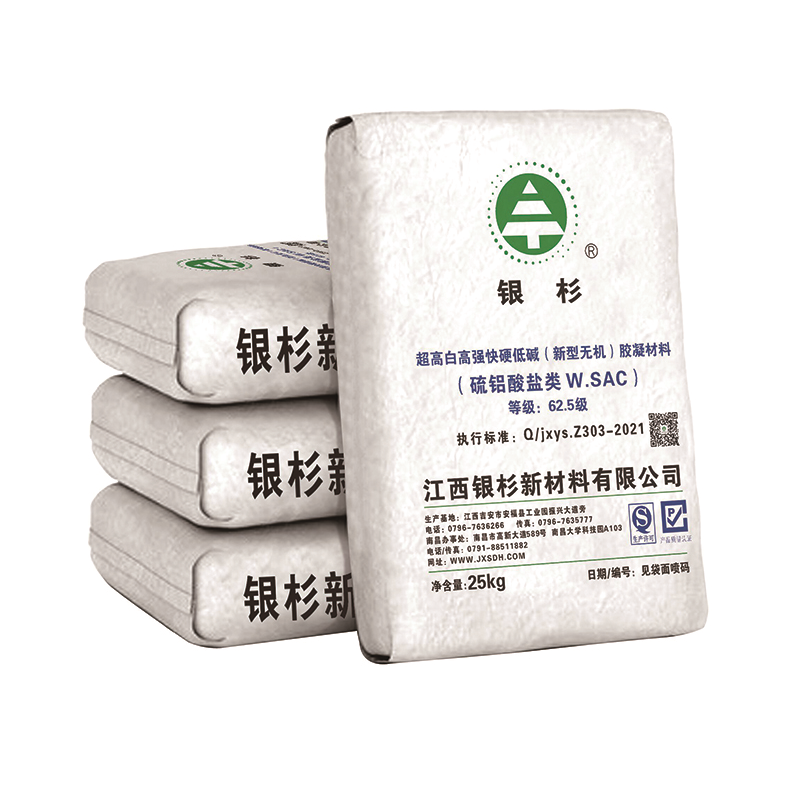

YINSHAN GREY CSA Cement

Application

White CSA cement is a special Calcium Sulfo Aluminate cement (CSA) designed for decorative concrete, terrazzo, flooring, glass fiber reinforced concrete (GFRC), dry-mixed mortars, architectural precast, fiber cement and more. Specially selected high purity raw materials, optimized calcination and carefully monitored grinding guarantee a consistent white color.

Certified Product Manufactured under GB/T 19001-2008 IDT ISO9001:2008 Quality Management System.

Specification

| Chemical parameter analysis | |||

| SiO2 | 7.81 | ||

| Al2O3 | 37.31 | ||

| Fe2O3 | 0.14 | ||

| CaO | 40.78 | ||

| MgO | 0.37 | ||

| SO3 | 11.89 | ||

| f-CaO | 0.07% | ||

| Loss | 0.29 | ||

| Physical parameter analysis | |||

| Blaine finenes(cm2/g) | 4500 | ||

| Setting time(min) | Initial (min)≥ | 15 | Based on customer request |

| Final≤ | 120 | ||

| Compress strength(Mpa) | 6h | 25 | |

| 1d | 55 | ||

| 3d | 65 | ||

| 28d | 72 | ||

| Flexural strength(Mpa) | 6h | 6.0 | |

| 1d | 9.0 | ||

| 3d | 10.0 | ||

| 28d | 11.0 | ||

| Whiteness (hunter) | Over 91% | ||

Benefits

Ideal for making “ fast set concrete”

Allows for quick-demolding

Rapid return to service

Compatible with various aggregates

Reduces efflorescence

Calcium Sulfoaluminate Cement increases strength, reduces set times, and decreases shrinkage of concrete mix designs, used as a stand-alone binder or blended with white portland cement delivers high early strength to incredibly durable concrete and mortar. Conventional retarding admixtures can be used to increase working time sacrificing early strength development

Calcium Sulfoaluminate Cement is ideal for applications requiring high early strength and rapid setting. Concrete and mortar formulated with CSA cement are capable of obtaining the 28-day strength of ordinary cement in just one day.

Suitable projects include

Concrete runway repair

Bridge deck repair

Tunneling

Roadway repairs

Non-shrink grout

Concrete floor overlayment

Zero to Low Shrinkage

CSA cement achieves higher early strength than portlandcement allowing for the formulation of non-shrink and low-shrinkage concrete and mortar products. CSA cement utilizes nearly 100% of the mix water during hydration process, leaving very little water to contribute towards shrinkage. Hydration temperature is considerable lower than comparable quick setting systems .Additionally, because of high early strength development, little or no shrinkage occurs after initial set.